Assembly and Testing Equipment

Over two decades of experience in offering high quality automation solutions allows us to custom design and build single station assembly machines as well as test/inspection machines that suit your specific manufacturing process requirements. Our in-house design capability allows for total control of the project from start to finish. Adhering to ISO 17025 standards, we provide design plus fabrication services for a range of assembly and testing equipment applications in automotive, medical, as well as packaging industries.

A 10-ton hoist crane at our machine shop enables us to safely handle your custom built assembly equipment within our 40 feet by 80 feet build floor. Manufacturers seeking to increase the efficiency and accuracy of their assembly processes can benefit from our customized manufacturing services for mechanical, electrical, pneumatic, and robotic assembly equipment. We have previously designed and manufactured a unique range of assembly equipment, including automotive battery case heat-sealing machines, continuous motion conveyors for assembling heavy-duty starting motors, bearing presses for transmission cases, and assembly machines for motor starters.

For additional information or for your personal consultation regarding your component or product please select the “RFI” request information selection button to begin your communication.

Specifications

- Product Categories

-

Assembly Machines for Automated Door Latch Components

Assembly Machines for Motor Starters

Bearing Presses for Transmissions

Continuous Motion Conveyors for Assembling Heavy Duty Starting Motors

Eddy Current Inspection Machine for detecting imperfections in production parts

Examples

- Eddy Current Inspection Machine

-

Sub-assemblies are stopped on the conveying system and checked for metallurgical imperfections on or under the surfaces.

larger image

- Starting Motor Case Assembly Machine

-

The case is placed in the nest with the inner winding assembly and then screws are driven into the assembly while DC screwdriver guns are setting the torque setting.

larger image

- Automated Door Latch Assembly Machine

-

The door latch components are assembled to the door latch frame and tested for function and locking pressure release.

larger image

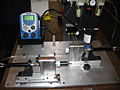

- Transfer Case Seal Installation Press

-

Seal Insertion Press

larger image

- Automated Adhesive Applicator

-

Small air motors drive round magnetic components for assembly while applying a precise amount of adhesive.

larger image

- Television Tube Frame Welding Machine

-

The inner frame of a cathode ray tube is welded to the location clips for mounting into the panel glass.

larger image

Other Information

- Acceptable Drawing Formats

-

- Solidworks

- Parasolids

- STP / STEP

- Inventor

- Solid Edge

- CATIA (*.cgr)

- ProE / Creo

- Unigraphics / NX

- Rhino (*.3dm)

- AutoCAD

- Certifications

-

- ISO 17025 Certification and Scope

- Industries Served

-

- Aerospace

- Orthopedic Implants

- Medical Instrumentation

- Automotive Components and Castings

- Advantages

-

Kent Machine Inc. is a one-stop, quick-turnaround shop for gauge, machine and fixture design, build and calibration. We design, fabricate, build, calibrate and test our custom gauges and inspection equipment so you can confidently use them in production immediately upon receipt of your order.