Design and Engineering Services

At Kent Machine, Inc. complete engineering support from concept through run off is provided for customers. Our engineering department utilizes 3-D design of single station assembly or test machines. Pneumatic and electrical schematics are always supplied at the completion of any project. For customers who prefer 2-D formats, we support AutoCAD drawings too. KMI can supply turnkey services in single station assembly and test/inspection machines. We can also provide turnkey solutions for work holding fixtures and custom designed attribute as well as variable gauges. The Kent Machine metrology lab provides design with reverse engineering capability.

Experience in working with different materials allows us to provide expert assistance as well as guidance in material selection based on material properties or its applications. Chemical composition and material facts are explained to customers along with images of our previous projects, prior to selecting the appropriate material for their gauges.

Work holding fixtures are developed according to part geometric specifications supplied by the customers. Any type or configuration of a gauge can be custom designed to suit the part features and expected dimensional standards. Our mechanical, electrical, as well as pneumatic design and drafting services comply with ANSI 14.5 GD & T standards for geometric dimensioning & tolerancing. Testing and calibration of gauge designs are performed in compliance with ISO 17025 standards.

For additional information or for your personal consultation regarding your component or product please select the “RFI” request information selection button to begin your communication.

Capabilities

- Capabilities

-

Mechanical, Electrical, and Pneumatic Design Engineering

New Product Designing

Reverse Engineering

Turnkey Engineering Services

- Products Designed

-

Assembly Machines

Fixtures

Gauges

Jigs

Stamping Dies

Tooling

- Design Capabilities

-

Examples

- 3-D Design of Single Station

-

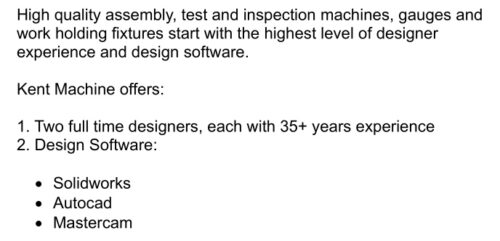

3-D design of single station assembly and test machines with pneumatic and electrical schematics are always supplied at the completion of any project.

- Work Holding Fixtures

-

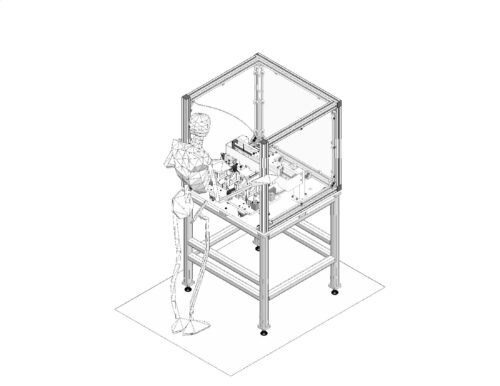

Work holding fixtures are always concepted around part geometry supplied by the customer. Hydraulic, pneumatic or manually activated assemblies can be designed to achieve the customer’s expectations.

larger image

- Types and Configurations of Gauges

-

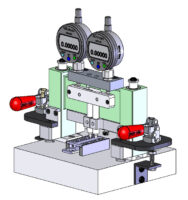

Gauge 001

larger image

Gauge 005

larger image

Gauge 004

larger image

Gauge 003

larger image

All types and configurations of gauges can be custom designed to fit the part features. From attribute to variable with data collection can be managed through the design department.

larger image

- Detailed Drawings

-

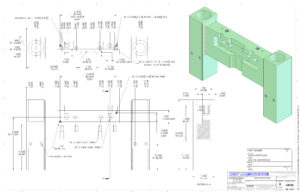

Detailed drawings with specific tolerances are created from the solid models.

larger image

Other Information

- Acceptable Drawing Formats

-

- Solidworks

- Parasolids

- STP / STEP

- Inventor

- Solid Edge

- CATIA (*.cgr)

- ProE / Creo

- Unigraphics / NX

- Rhino (*.3dm)

- AutoCAD

- Certifications

-

- ISO 17025 Certification and Scope

- Industries Served

-

- Aerospace

- Orthopedic (Implants)

- Medical Instrumentation

- Automotive (Engine /Transmission)

- Advantages

-

Kent Machine Inc. is a one-stop, quick-turnaround shop for gauge, machine and fixture design, build and calibration. We design, fabricate, build, calibrate and test our custom gauges and inspection equipment so you can confidently use them in production immediately upon receipt of your order.