Kent Machine: Precision Machining without Compromise

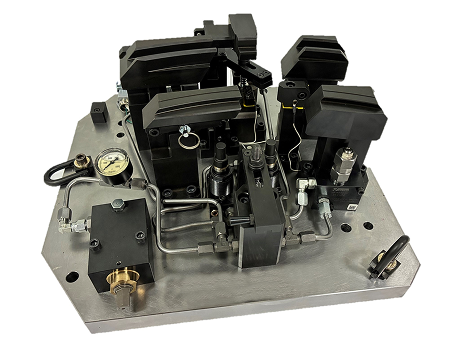

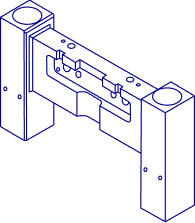

Kent Machine delivers high-precision machining, specializing and designing high-performance gauges and fixtures.

Got a manufacturing challenge that other shops say is impossible? Try us—we want the biggest challenges you’ve got.

Kent Machine: Precision Without Compromise.

Talk to a Kent Machine Expert

How much is the wrong precision machining costing you—and your customers?

We know what you’ve been going through.

- You can’t count on your supplier to source materials

- Your supplier won’t hold tight tolerances

- Your supplier treats deadlines as suggestions

- Your parts aren’t always to spec

- You can get someone on the phone when they feel like talking, not when you need them

Kent Machine is different. Kent Machine gets results and delivers on its commitments.

That’s why when companies partner with Kent Machine, they partner with us for years.

Kent Machine delivers the precision machining you’ve been looking for

Kent Machine prides itself in providing the reliable, high-quality precision machining that helps our partners thrive.

Here’s a few of our specialties:

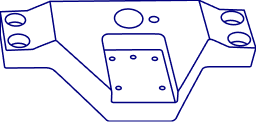

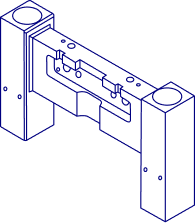

Complex parts

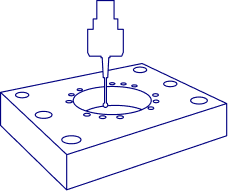

Rigorous quality control

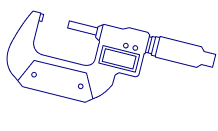

Designing and building a diverse range of gauges

Gauge calibration

Flush Pins & Tapers

Prototype for precise, production low-volume machining

One-off high-difficulty jobs

Work-holding fixtures

With decades of combined experience, our engineers are eager for your biggest challenge.

Don’t see what you’re looking for? Talk to us.

Talk to a Kent Machine Expert

Industries We Serve

Medical

Aerospace

Defense

Industrial

Nuclear

Automotive

Don't Just Take Our Word for It

Kent Machine always nails the tight tolerances we need, down to 0.005mm. Plus, having Brian stop by to check in really sets them apart from other suppliers.

Anthony Lee - Beretta

Let's get started

Get the High Quality Parts you need without Excuses.

Talk to a Kent Machine Expert