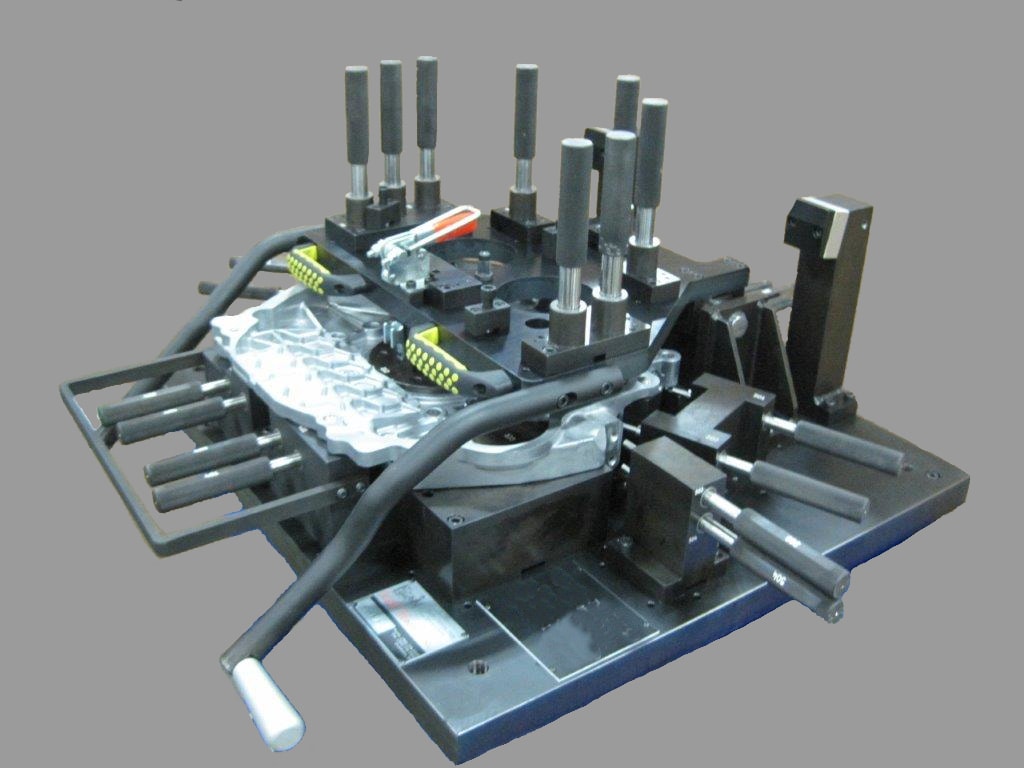

Design & Manufacture of a Custom Attribute Gauge

(click on thumbnail to enlarge)

Kent Machine was contacted by an automotive casting manufacturer to design an attribute gauge to inspect thirty-three hole locations after the machining operation. After the design was completed and approved, Kent Machine manufactured the gauge using pre-hardened steel and tool steel components. Most of the components were heat treated and black oxide coated at our facility, reducing the lead time required to deliver the gauge to the customer. The gauge was then inspected in our ISO 17025 accredited lab and supplied to the customer with a full ISO 17025 calibration report.

This project exemplifies Kent Machine’s ability to design and fabricate precision products, offering customers a reliable low cost solution. Contact Kent Machine for more information on what they can do to address your engineering design and fabrication needs.

Highlights of this Custom Attribute Gauge

- Design & FabricationCapabilities Applied/Processes

-

Primary:

Mechanical Design

Component Sourcing

Machining- Turning

- Milling

- Grinding

Assembly

Heat Treating

Part Marking – Engraving

- Material Used

-

Pre-Hard Steel and Tool Steel

- Material Finish

-

Hardened to Rc 58 – 62 and Black Oxide

- In process testing/inspection performed

-

Functionality Testing

- Volume

-

1

- Delivery Location

-

Ohio

- Product Name

-

Attribute Gauge