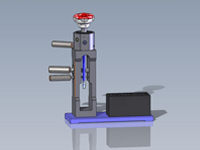

Fabrication of a Nail Hole Location Gauge for the Medical Implant Industry

(click on thumbnail to enlarge)

Kent Machine (KM) was selected by a Warsaw, IN medical industry customer to create the Nail Hole Location Gauge product shown below. KM’s superior mechanical design, component sourcing, fabrication, and assembly capabilities allowed the creation of a solution that fully satisfied the requirements of the customer. A hole/slot inspection gauge design was utilized, modified to follow customer defined specifications. The design was validated through comprehensive functional testing and inspection. The entire project from concept to delivery was completed in only 10 weeks.

Kent Machine’s advanced capabilities and ability to deliver innovative designs ensured that this customer received a reliable, precise gauge system that would provide a long trouble free service life.

To learn more about this project or the processes used to create it, see the table below or contact Kent Machine directly.

Highlights of this Custom Designed & Fabricated Medical Tool

- Product Description

-

This gauge is used to Inspect Slot and Hole locations.

- Design & Fabrication Capabilities Applied/Processes

-

Primary:

Mechanical Design

Component Sourcing

Fabrication

Assembly

- In process testing/inspection performed

-

Functional Inspection

- Volume

-

2

- Delivery/Turnaround Time

-

10 Weeks

- Delivery Location

-

Warsaw, Indiana

- Standards Met

-

Customer Specifications

- Product Name

-

Hole/Slot Location Gauge – Nail