Work Holding Fixtures

Kent Machine provides custom work holding fixtures for a wide range of applications including: Horizontal and Vertical CNC Machining, 4 and 5 Axis Machining, Robotic Welding, Automatic Presses, Inspection and Assembly. Our experience in designing and building custom gauge fixtures allows us to build work holding fixtures with ease. Whether you need manual or automatic load, manual, pneumatic or hydraulic clamping, light curtains or communication with your machine, Kent Machine can design and build a fixture that will meet your requirements. Our hydraulic integration capabilities include both internal and external porting. All fixtures are designed to conform to ANSI 14.5 GD & T standards.

We are staffed with an experienced and capable design team that offers services for the complete design of custom work holding fixtures to your specifications. 2D and 3D models of parts are analyzed with AutoCad and SolidWorks, in the design process. In addition, after fabrication, all of our fixtures are inspected in our in-house ISO 17025:2017 certified calibration lab.

For additional information or for your personal consultation regarding your component or product please select the “RFI” request information selection button to begin your communication.

Specifications

- Lead Times

-

At Kent Machine, Inc., our typical lead time is 4-6 weeks for build to print fixtures and 8-12 weeks for design and build fixtures. Contact us for a delivery quote for your specific project.

- Product Categories

-

Attribute and Variable Styled Check Fixtures

Cooling Fixtures

Hydraulic Clamping Fixtures

Manual Clamping Drill Press Fixtures

Pneumatic Fixtures for Robotic Welding Cells

- Types of Integration

-

Electrical

Hydraulic (Internal and External)

Pneumatic

- Secondary Operations

-

Heat Treating

Cryogenic Freeze (Microstructure Stress Relieve)

Capabilities

- Equipment List

-

Equipment List (PDF – 47KB)

Equipment List (PDF – 47KB)

- Specialty Capabilities

-

Kent Machine Inc. has in-house specialty Heat Treating and Cryogenic Freeze capabilities to insure the quickest turnaround, highest quality, and dimensional consistency for your gauging and checking equipment needs. Our on-site Cryogenic Freeze cycle in (-270°F) Liquid Nitrogen (HT>Draw>Freeze>Draw) stabilizes and stress relieves the material’s molecular structure for maintaining dimensional consistency during the final grinding process, likewise assuring only the tightest tolerances and finest surface finishes for the most precise gauges and inspection fixtures.

- Specialty Applications

-

KMI specializes in ISO 17025 accredited inspection, and the design and building of gauges and inspection equipment for:

- Orthopedic Implants

- Aircraft Components

- Medical Instrumentation

- Automotive Components and Castings

- Design Capabilities

-

Examples

- Manual Clamping Drill Press Fixture

-

Locates part with angled holes and indexes every 90 degrees by means of a manual shot pin.

larger image

- Hydraulic Clamping Fixture

-

Hydraulic clamping fixture that is activated by the machine tool after the operator manually loads onto the locator nest.

larger image

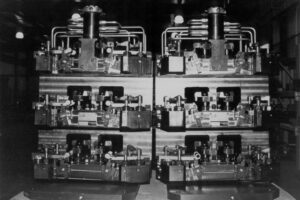

- Multi-Part Hydraulic Clamping Fixture

-

Multi-part hydraulic clamping fixture with rotary union for machining parts from both sides of tombstone.

larger image

Other Information

- Acceptable Drawing Formats

-

- Solidworks

- Parasolids

- STP / STEP

- Inventor

- Solid Edge

- CATIA (*.cgr)

- ProE / Creo

- Unigraphics / NX

- Rhino (*.3dm)

- AutoCAD

- Certifications

-

- ISO 17025 Certification and Scope

- Industries Served

-

- Aerospace

- Orthopedic Implants

- Medical

- Instrumentation

- Automotive Components and Castings

- Advantages

-

Kent Machine Inc. is a one-stop, quick-turnaround shop for gauge, machine and fixture design, build and calibration. We design, fabricate, build, calibrate and test our custom gauges and inspection equipment so you can confidently use them in production immediately upon receipt of your order.